.png)

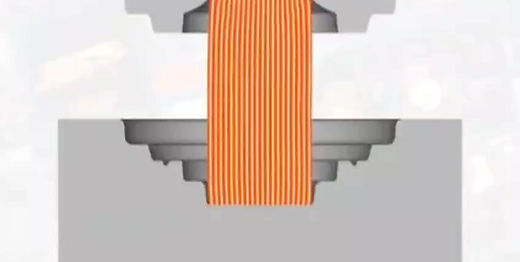

TOOL MANUFACTURING

We take pride in its robust in-house tool manufacturing capabilities, which are integral to maintaining high standards of quality and precision in our forging operations. Our advanced Die Shop and tool-room form the foundation of our success in producing superior forged and machined components.

Equipment and Technology

Our facilities feature advanced CNC and VMC machines, modern machining centres, and the latest software, enabling us to produce high-precision dies and tools for diverse forging applications.

Quality Control

Quality is central to our tool manufacturing process, with rigorous checks before production, strict control measures throughout, and innovative techniques used to extend tool life.

Skilled Workforce

Our skilled toolmakers use their expertise and the latest technology to design and manufacture tools that meet precise requirements, select the right tool steels for specific applications, and ensure optimal material selection for each project.

Advantages of In-House Tool Manufacturing

• Tight control over quality

• Reduced lead times

• Quick response to custom requirements

• Ability to maintain high standards across our diverse product range